logic brinell hardness tester 3000 kg load|kb series brinell tester : wholesaling The tester applies up to a 3,000 kg load on a 10mm ball, making a lasting impression, which is available for re-reading at any time. . This portable Brinell hardness tester meets all international standards for Brinell testing including . Tiki Wonders bet limits consist of coin values ranging from 0.01 to 0.50, up to 30 paylines, and 4 bet levels, making for a wide range of betting options for all limit preferences. A bet level 1 spin with a coin value of 0.01 on all 30 . Ver mais

{plog:ftitle_list}

webDemi Sutra Actor, Writer Born January 10, 1991 in Washington, District of Columbia, USA Demi Sutra was born on January 10, 1991 in Washington, District of Columbia, USA. She is an actress and writer. Connections Mona Wales Maddy O'Reilly Marcus London

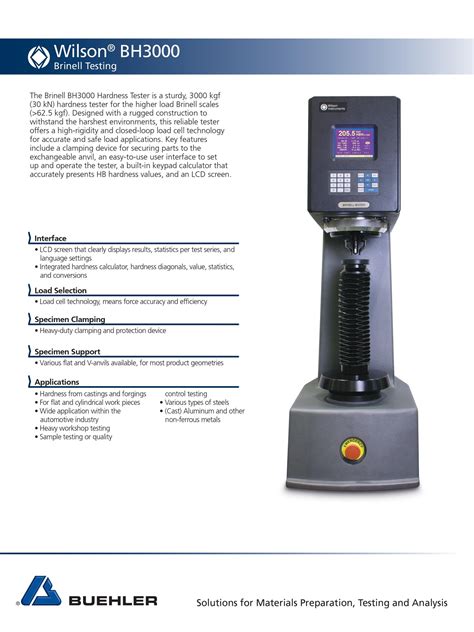

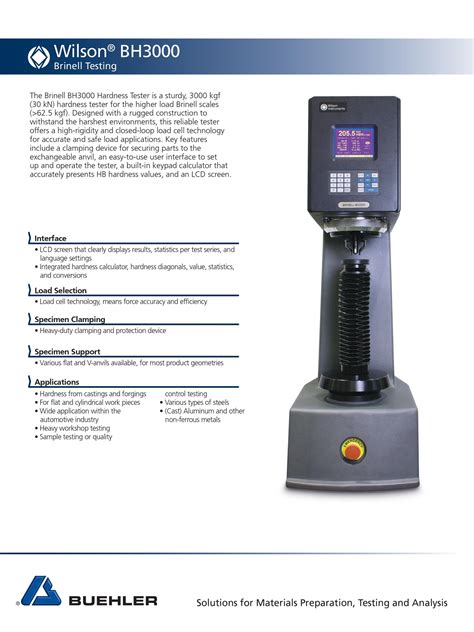

Range: 80-500. Made from highest quality material to ensure the most uniform and repeatable blocks available. Scale and general hardness range should be submitted to us with your purchase order for these blocks. A traceable .The Brinell BH3000 Hardness Tester is a sturdy, 3000 kgf (30 kN) hardness tester for the higher load Brinell scales (>62.5 kgf). Designed with a rugged construction to withstand the harshest .The KB Series hardness tester applies up to 3000 kg load on a 10mm ball, making a visible indentation that is read using a Brinell scope or our B.O.S.S. system. The calibrated accuracy is better than 0.5% of the applied load.The tester applies up to a 3,000 kg load on a 10mm ball, making a lasting impression, which is available for re-reading at any time. . This portable Brinell hardness tester meets all international standards for Brinell testing including .

The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110. This lightweight, portable tester is ideal for virtually any size or shape of metal specimen. . The tester applies up to 3000 kg load on .

And this hardness tester can act as both a bench type or portable hardness tester for use in the field. The PHT-5050 portable Brinell hardness tester meets all Brinell standards, including ASTM E-110, and relevant Brinell .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

The tester is used for determining the Brinell hardness of un-quenched steel, cast-iron, nonferrous metals and soft bearing alloys. This tester can be used in metallurgical . and so on for the other test loads up to 3000. 750 kg load may be set up with 187.5, 62.5 and 500 kg weights. Make certain each weight is orientedBrinell hardness testing is a commonly used method for determining the hardness of metals and alloys. . Load (kg) Brinell hardness number: 500: 26 – 100: 1500: 80 – 300: 3000: 160 – 600: While the Brinell hardness test is most commonly used to test metals and alloys, it can be used on other materials too. Typical Brinell hardness .Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .HB (3000) The Brinell Hardness Test, commonly used for metallic materials, determines hardness by applying a known load (3000, 1500, or 500 kgf) to the surface of the test specimen via a hardened steel or diamond ball of prescribed size (10 mm in diameter).

wilson brinell tester

Macro hardness testing for your production or laboratory processes according to Vickers, Knoop, Brinell, Rockwell, carbon testing & plastics testing Load range from 0.3 to 3,000 kg More information and request for quotation The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. . leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material .The KB Series hardness tester applies up to 3000 kg load on a 10mm ball, making a visible indentation that is read using a Brinell scope or our B.O.S.S. system. The calibrated accuracy is better than 0.5% of the applied load.

For a standard Brinell hardness test, a 10 mm ball and a load of 3,000 kg are used. After the load is applied and then released, the indentation is measured using a microscope to be 2.737 mm in diameter, what is the Brinell hardness number (BHN)? 9. If a Rockwell hardness test has been performed on a steel and the hardness is determined to be .Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings. . and accuracy by automating various aspects of testing, from load application to indentation measurement. . Automatic Hardness Tester - MRS JET .4. THE ASTM BRINELL TEST METHOD The 7000 Series Brinell uses a fixed 3000 kg load (optionally 500 kg or other load) and a 10 mm tungsten ball indenter (optionally 5 mm). The following general information is included for the benefit of the user. Brinell testing is covered by the ASTM standard E-10.The operator simply places the specimen between the anvil and the test head, cranks the test head down onto the specimen, locking the tester in place, closes the pressure release valve, and pulls the hydraulic lever until the desired load .

The Brinell Hardness Test, commonly used for metallic materials, determines hardness by applying a known load (3000, 1500, . As a result, the 3000 kgf load yields HB measures between 160 and 600; the 1500 kgf load, HB 80 to 300; and the 500 kgf load, HB 26 to 100. Smaller loads (e.g., 250, 125, 100 kgf) can be used for softer metals.

Brinell Hardness Testing. Engineering Metals and Materials Table of Contents. Brinell Hardness Testing - In this test a standard constant load, usually 500 to 3,000 kg, is applied to a smooth flat metal surface by a hardened steel-ball type indenter, 10 mm in diameter. The 500-kg load is usually used for testing nonferrous metals such as copper and aluminum alloys, .

The Brinell Hardness tester that shows the largest indentation among all the hardness tests is able to reflect the comprehensive features of the material ,and the test is unaffected by the organization microscopic segregation and the compositional unevenness of the specimen; and hence it is a hardness testing with high precision.DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left.

Computerized Film Thickness Tester distributors

Brinell Test Blocks. 3000 KG LOAD. HB3000. 8.00 USD. EACH. Qty. Product Description. NIST traceable. . Scale and general hardness range should be submitted to us with your purchase order for these blocks. A traceable calibrated test certificate is supplied with each test block. The test results will conform to the appropriate ASTM .5. In a Brinell hardness test, a 3000 − kg load is pressed into a specimen using a 10 mm diameter ball. The resulting indentation has a diameter of 5 mm.Determine the Brinell hardness number for the material. (142.5) 6.(More challenging) A simple cube of material is inserted into a snug fitting test frame (as shown below) and then a 13, 125 N load is applied on the top surface.4. THE ASTM BRINELL TEST METHOD The 7000 Series Brinell uses a fixed 3000 kg load (optionally 500 kg or other load) and a 10 mm tungsten ball indenter (optionally 5 mm). The following general information is included for the benefit of the user. Brinell testing is covered by the ASTM standard E-10.

Drop Dart Impact Tester distributors

The Pin Brinell’s load to indentation size ratio provides a displacement that is equivalent to the most common Brinell test (3000 kg load, 10mm ball). The Brinell values are arrived at using the standard Brinell formula. Available in two models: the .The Brinell hardness test consists in indenting the metal surface with a 10-mm-diameter steel ball at a load of 3,000 kg mass (∼29400 N). For soft metals the load is reduced to 500 kg to avoid too deep an impression, and for very hard metals a tungsten carbide ball is used to minimize distortion of the indenter.The King Portable Brinell Hardness Tester is the most reliable, user-friendly and affordable portable Brinell tester and the ONLY portable Brinell tester on the market that is calibrated and certified per ASTM E-10 standards. . The tester applies up to a 3,000 kg load on a 10mm ball, making the required impression, which is available for re .

3. In a Brinell hardness test, a 1500-kg load is pressed into a specimen using a 10-mm-diameter hardened steel ball. The resulting indentation has a diameter = 3.2 mm. (a) Determine the Brinell hardness number for the metal. (b) If the specimen is steel, estimate the tensile strength of the steel.The King Brinell Hardness Tester offers accurate, portable hardness testing for metallic materials, compliant with ASTM E-10 and E-110 standards. Easy to use, with a 3,000 kg load capacity.

wilson brinell hardness tester

wilson brinell 3000

WEBLeer más artículos. Últimas noticias y actualidad de los famosos: cotilleos, reportajes, entrevistas y la última hora de los famosos españoles y de celebrities internacionales con un toque CUORE.

logic brinell hardness tester 3000 kg load|kb series brinell tester